4News

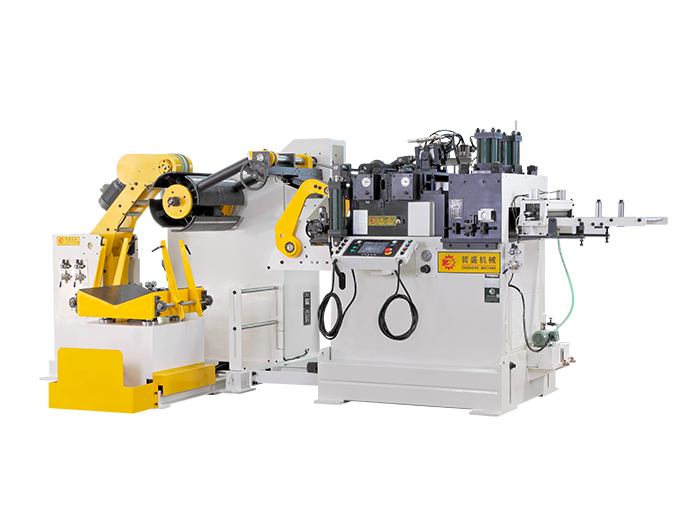

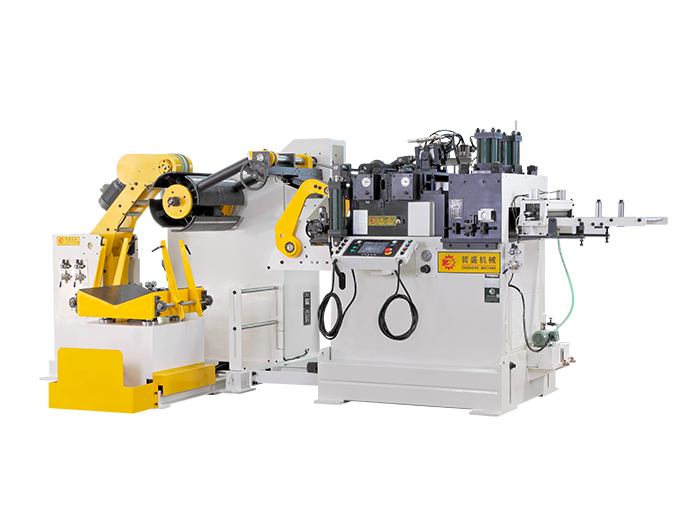

Constantly improving the quality and practicality of the feeder is the customer's demand and the direction of Shixiang's efforts. In recent years, the three-in-one feeder has won wide acclaim from customers for its excellent performance, high efficiency and stable production capacity. With the accumulation of experience and extensive feedback from customers, as well as the exploration and development of new technologies and materials by Shixiang, after 13 years of accumulation and development, the three-in-one feeder can be more excellent and efficient. "The beauty of wisdom" helps customers "gain" in the future.

Nine performance characteristics of the three-in-one feeder:

1. On the spindle of the material rack, the pneumatic material support arm and the material material limit rod are respectively restricted from the inner and outer directions, so that the rotation is more stable.

2. The material pressure arm of the material frame is changed from the traditional hydraulic pressure type material to the pneumatic type pressure material, which is safe, reliable, environmentally friendly and energy-saving, reduces noise, reduces the volume of the oil pressure station and reduces the use cost. The horizontal motor is mounted on the thick plate pressing arm to drive the pressing wheel to rotate and tighten the material to ensure that the material does not rebound and maximize the safety of production.

3. Install the material detecting device to automatically detect the rotation angle of the material spindle and the thickness of the material to ensure the precise control of the spindle speed.

4. The coil unwinding control is changed from the traditional group of photoelectrics to two groups of photoelectrics. The material only needs to block one of the photoelectrics to ensure that the rack stops rotating and avoids damage to the equipment caused by photoelectric failure.

5. Add a pneumatic feeding platen device at the feeding inlet of the leveling feeding machine head, and press the material head to automatically feed into the leveling machine, which is stable and reliable.

6. increase the perspective window to ensure the safety of operators.

7. The processing technology of leveling and feeding drum is greatly optimized and improved, and its dimensional accuracy and wear resistance are improved.

8. using the optimized electronic control system with: Japan Mitsubishi PLC, Germany Eston servo motor, high-precision worm gear reducer, metal bellows coupling, no transmission clearance, no corner error, to ensure feeding accuracy and stability .

9. The material rack, leveling and feeding machine are controlled by touch screen, with real-time monitoring and running status detection function. The operation is safe and stable, and the operation is simple and worry-free.